Engineering

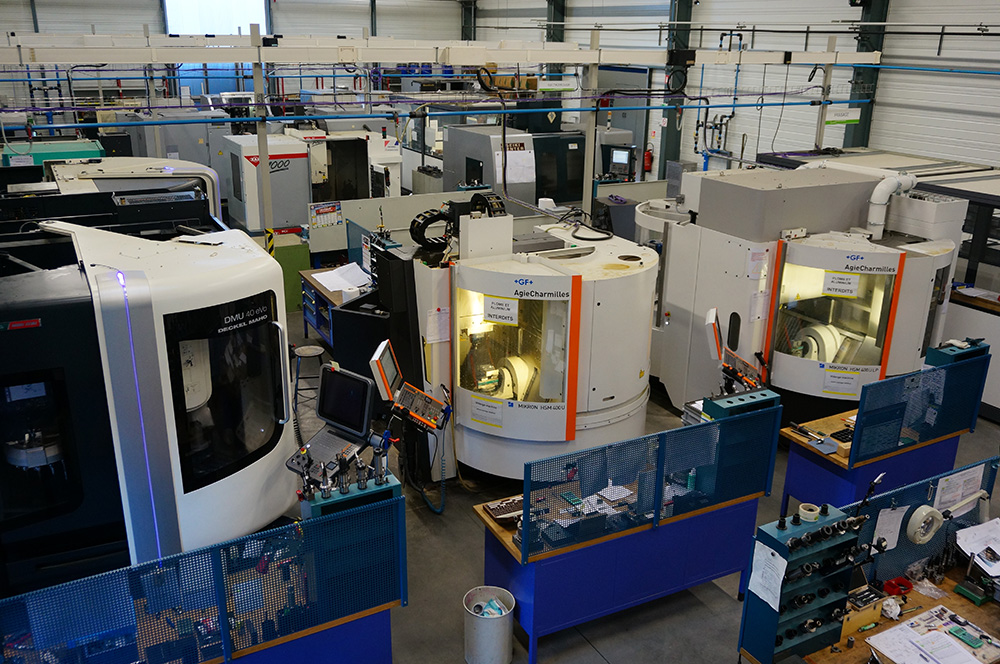

As a world-class supplier of surgical instruments for leading orthopaedic medical device manufacturers, EUCLIDE care is equipped for the most demanding tolerances and complex geometries.

We offer a very broad range of manufacturing capabilities with deep experience in manufacturing orthopaedic devices. Our hallmark is combining various technologies to make complicated products. Manufacturing capabilities include swiss-style machining, CNC turning and 3 to 5 axis milling, wire and sinker EDM, grinding, laser marking, sandblasting, finishing, acid cleaning bath or ultrasonic, passivation.

Raw Materials

Our fully validated facilities focus on the production of implantable medical devices. Sophisticated equipment and manufacturing processes enable us to efficiently manufacture a wide variety of implants and surgical instruments. We provide skilled machining and manufacturing of components and subassemblies from various materials like Titanium, Cobalt-Chrome, stainless steel of surgical quality, Tantalum, Nitinol as well as plastic materials like polyethylene, acetal, Teflon, natural PEEK or carbon PEEK.

Finishing – Quality Control – Tracing

Your team can count on us to be a reliable and experienced partner in all stages of your product lifecycle up to polishing, bead blasting, assembly, welding, laser marking, cleaning and passivation. We deploy our resources to meet your unique manufacturing and engineering needs.

Our experienced design & development team is available to assist in the development of custom-designed instruments or modifications to one of our standard instruments. Leverage our experts for the development of instrumentation for your next launch.

As your silent partner, EUCLIDE Care engineering and production professionals will work directly with your engineers to assist in development, quality and performance enhancements, as well as improved manufacturability and assembly. Whether it’s a new product you are trying to get to market or a long-term production item that needs updating